| Availability: | |

|---|---|

PC

Screw thread with high sealing request,high accurancy of dimension

High standard of appearance, make PL under 0.05mm

To ensure the PL step,use of combination processing, combination polishing. And one-time mirror electric tapping of the combination of gongs and teeth to ensure the appearance of the product and meet the requirements of PL on appearance.

Through professional simulation analysis, improve deformation issues, with precision machine to ensure dimension.

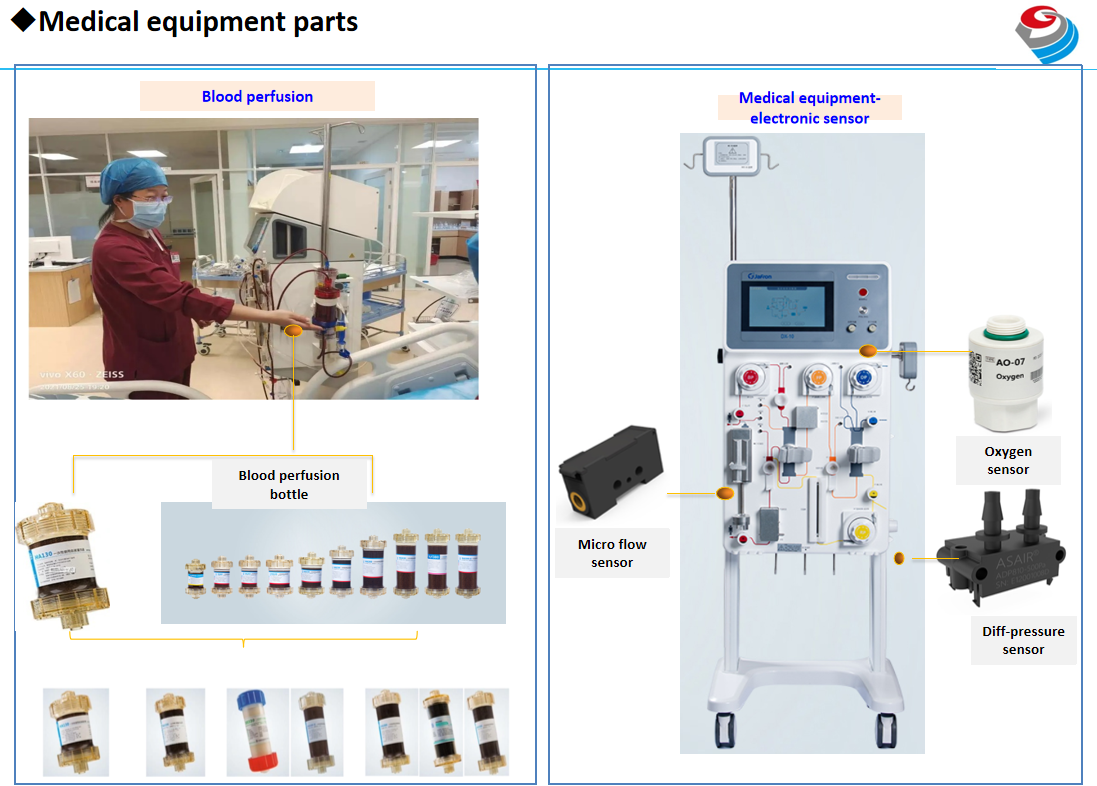

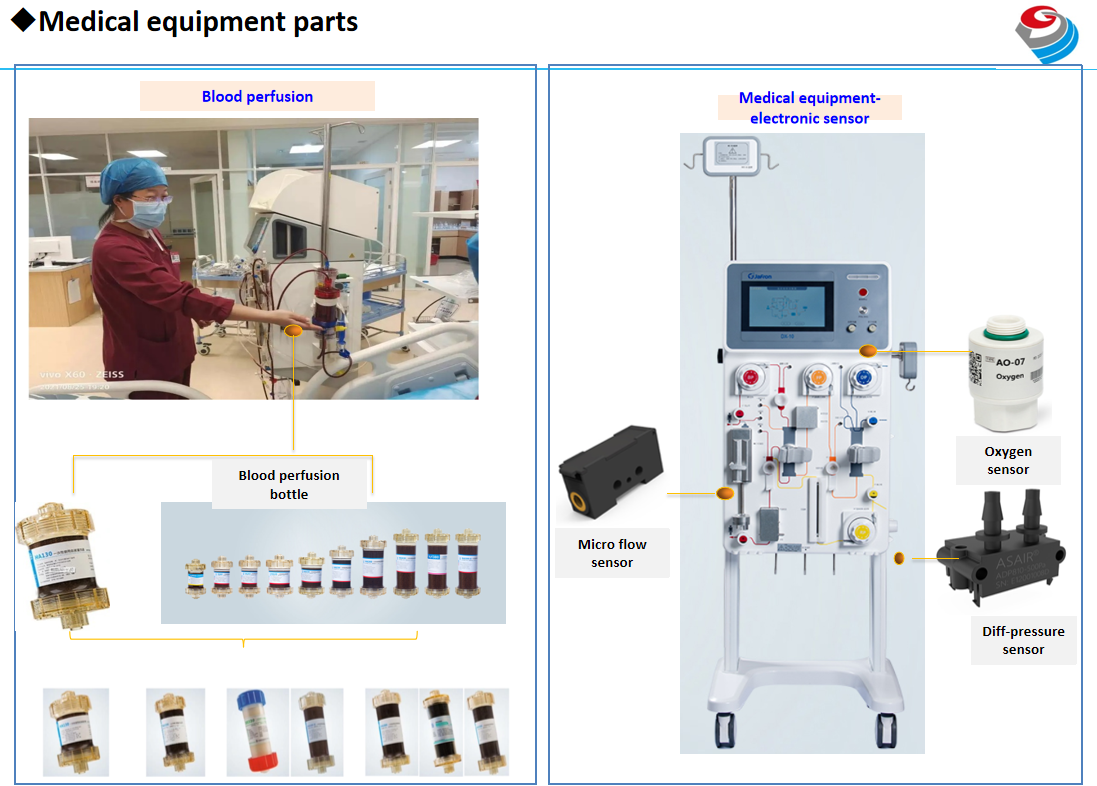

Precision Disposable Hemoperfusion Cartridge Injection Mold

Injection Molds for Disposable Hemoperfusion Cartridge: High-Standard Design and Manufacturing Solutions

PC (Polycarbonate)

The injection mold is designed with high sealing performance to prevent any leakage, ensuring the product meets stringent medical standards.

The mold maintains extremely tight tolerances, ensuring the highest accuracy for the dimensions of the final product, which is crucial in medical applications.

Flawless Appearance | Advanced processes are used to ensure a smooth and flawless finish, improving both functionality and aesthetics of the product. |

Splitting Line Control | The mold's splitting line is controlled to less than 0.05mm, ensuring a safe and stable product in application. |

Combined Processing | Utilizes combined processing methods to improve both efficiency and precision during manufacturing. |

Combined Polishing | The product surface is polished to perfection, ensuring smoothness and flawlessness for medical-grade components. |

Integrated Thread Mirror Finish | Achieves a mirror finish on the threaded sections to ensure a flawless appearance and excellent sealing performance. |

Professional Simulation Analysis | GDM uses professional simulation techniques to identify and mitigate potential mold deformation issues, optimizing the production process |

High-Precision Machine Tool Processing | The use of advanced Makino high-precision machines ensures that each mold meets the required dimensional accuracy and quality standards. |

Comprehensive Quality Control | Rigorous quality control throughout the production process ensures that each mold meets medical industry standards and reliability requirements. |

The Precision Disposable Hemoperfusion Cartridge Injection Mold is primarily used in the medical field for producing disposable hemoperfusion cartridges, which are essential for performing hemoperfusion procedures in hospitals and medical facilities. This mold is also suitable for use in pharmaceutical, healthcare, and laboratory equipment industries.

| Appearance Standards |

The mold ensures a high standard of appearance, maintaining a PL (parting line) step under 0.05mm for seamless integration into medical devices.

| Dimensional Precision |

Every aspect of the mold is crafted with high precision, ensuring that the final product meets stringent size and tolerance requirements.

Mirror Electric Tapping for Thread Finish: GDM employs a one-time mirror electric tapping process to combine gongs and teeth, ensuring the appearance and quality of the threaded section meets medical standards.

Combination Processing and Polishing: The combination of advanced processing and polishing methods guarantees the best quality in terms of both functional performance and aesthetics.

Splitting Line Control: Maintaining the splitting line under 0.05mm ensures that the final product is both safe and stable in medical applications.

1. What material is used in the Precision Disposable Hemoperfusion Cartridge Injection Mold?

The mold is made from PC (Polycarbonate), known for its excellent transparency, impact resistance, and mechanical properties, making it suitable for medical applications.

2. How precise is the machining of the Precision Disposable Hemoperfusion Cartridge Injection Mold?

The mold ensures high-dimensional accuracy and maintains the PL step under 0.05mm, ensuring flawless integration into medical devices.

3. How does GDM ensure the quality of the Precision Disposable Hemoperfusion Cartridge Injection Mold?

GDM uses advanced simulation analysis and high-precision machine tools like Makino to optimize the design and ensure that each mold meets strict quality standards.

4. What is the significance of the mirror finish on the threaded sections?

The mirror electric tapping process used by GDM ensures that the threaded sections of the mold are smooth, precise, and meet the necessary medical standards for sealing performance.

5. Can GDM handle custom mold designs for the medical industry?

Yes, GDM offers customized mold solutions, providing a complete service from design to production, ensuring that each mold meets the specific needs of medical device manufacturers.

Whether in the pharmaceutical, healthcare, or laboratory equipment fields, our medical injection molds offer superior performance and reliability, ensuring that every user receives the highest quality products and services.

Precision Disposable Hemoperfusion Cartridge Injection Mold

Injection Molds for Disposable Hemoperfusion Cartridge: High-Standard Design and Manufacturing Solutions

PC (Polycarbonate)

The injection mold is designed with high sealing performance to prevent any leakage, ensuring the product meets stringent medical standards.

The mold maintains extremely tight tolerances, ensuring the highest accuracy for the dimensions of the final product, which is crucial in medical applications.

Flawless Appearance | Advanced processes are used to ensure a smooth and flawless finish, improving both functionality and aesthetics of the product. |

Splitting Line Control | The mold's splitting line is controlled to less than 0.05mm, ensuring a safe and stable product in application. |

Combined Processing | Utilizes combined processing methods to improve both efficiency and precision during manufacturing. |

Combined Polishing | The product surface is polished to perfection, ensuring smoothness and flawlessness for medical-grade components. |

Integrated Thread Mirror Finish | Achieves a mirror finish on the threaded sections to ensure a flawless appearance and excellent sealing performance. |

Professional Simulation Analysis | GDM uses professional simulation techniques to identify and mitigate potential mold deformation issues, optimizing the production process |

High-Precision Machine Tool Processing | The use of advanced Makino high-precision machines ensures that each mold meets the required dimensional accuracy and quality standards. |

Comprehensive Quality Control | Rigorous quality control throughout the production process ensures that each mold meets medical industry standards and reliability requirements. |

The Precision Disposable Hemoperfusion Cartridge Injection Mold is primarily used in the medical field for producing disposable hemoperfusion cartridges, which are essential for performing hemoperfusion procedures in hospitals and medical facilities. This mold is also suitable for use in pharmaceutical, healthcare, and laboratory equipment industries.

| Appearance Standards |

The mold ensures a high standard of appearance, maintaining a PL (parting line) step under 0.05mm for seamless integration into medical devices.

| Dimensional Precision |

Every aspect of the mold is crafted with high precision, ensuring that the final product meets stringent size and tolerance requirements.

Mirror Electric Tapping for Thread Finish: GDM employs a one-time mirror electric tapping process to combine gongs and teeth, ensuring the appearance and quality of the threaded section meets medical standards.

Combination Processing and Polishing: The combination of advanced processing and polishing methods guarantees the best quality in terms of both functional performance and aesthetics.

Splitting Line Control: Maintaining the splitting line under 0.05mm ensures that the final product is both safe and stable in medical applications.

1. What material is used in the Precision Disposable Hemoperfusion Cartridge Injection Mold?

The mold is made from PC (Polycarbonate), known for its excellent transparency, impact resistance, and mechanical properties, making it suitable for medical applications.

2. How precise is the machining of the Precision Disposable Hemoperfusion Cartridge Injection Mold?

The mold ensures high-dimensional accuracy and maintains the PL step under 0.05mm, ensuring flawless integration into medical devices.

3. How does GDM ensure the quality of the Precision Disposable Hemoperfusion Cartridge Injection Mold?

GDM uses advanced simulation analysis and high-precision machine tools like Makino to optimize the design and ensure that each mold meets strict quality standards.

4. What is the significance of the mirror finish on the threaded sections?

The mirror electric tapping process used by GDM ensures that the threaded sections of the mold are smooth, precise, and meet the necessary medical standards for sealing performance.

5. Can GDM handle custom mold designs for the medical industry?

Yes, GDM offers customized mold solutions, providing a complete service from design to production, ensuring that each mold meets the specific needs of medical device manufacturers.

Whether in the pharmaceutical, healthcare, or laboratory equipment fields, our medical injection molds offer superior performance and reliability, ensuring that every user receives the highest quality products and services.

Create the advantages of GDM with the precision and high efficiency of manufacturing molds

Innovative Solutions in Mold Manufacturing by Zhuhai Greedaikin Precision Mold Company (GDM)

Unveiling GDM Precision: A Deep Dive into Mold Ejection Expertise

Unveiling Expertise in Mold Ejection System Design And Manufacturing

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.