Views: 0 Author: Site Editor Publish Time: 2024-10-30 Origin: Site

Injection molding is a critical process in modern manufacturing, enabling the mass production of complex plastic parts with high precision and efficiency. The success of this process heavily depends on the tools used, commonly referred to as 'injection tools'. These tools are responsible for shaping molten materials into desired forms, ensuring consistency and quality in the final product. This research paper delves into the various types of injection tools, their applications, and the technological advancements driving the industry forward. Understanding the intricacies of these tools is essential for manufacturers aiming to optimize their production processes and improve product quality.

In the following sections, we will explore the different types of injection tools, their components, and how they function within the injection molding process. Additionally, we will examine the role of **injection tools** in various industries, including automotive, healthcare, and consumer electronics. By the end of this paper, readers will have a comprehensive understanding of the tools used for injection molding and their significance in modern manufacturing.

For more insights into the latest advancements in injection molding, visit our Injection Mold page, where we offer detailed information on the various tools and technologies used in the industry.

The mold base is the foundation of any injection tool. It holds all the other components together and provides the structural integrity needed to withstand the high pressures involved in the injection molding process. The mold base is typically made from hardened steel or aluminum, depending on the application and production volume. Steel mold bases are more durable and suitable for high-volume production, while aluminum bases are lighter and more cost-effective for smaller production runs.

The cavity and core are the two primary components of an injection tool that shape the molten material into the desired form. The cavity is the hollow part of the mold where the material is injected, while the core is the solid part that forms the internal features of the part. Together, they create the negative space that defines the shape of the final product. The precision of the cavity and core is crucial for ensuring the dimensional accuracy of the molded part.

For high-precision applications, such as those in the automotive industry, the cavity and core must be manufactured with extreme accuracy. Visit our Automotive Injection Mold page to learn more about the specific requirements for automotive injection tools.

Once the material has cooled and solidified in the mold, the ejector system is responsible for removing the part from the mold. This system typically consists of ejector pins that push the part out of the mold cavity. The design of the ejector system is critical for preventing damage to the part during ejection. In some cases, air jets or mechanical arms may be used to assist in the ejection process, especially for delicate or complex parts.

The cooling system is an essential component of the injection tool, as it controls the temperature of the mold during the injection process. Proper cooling is necessary to ensure that the material solidifies evenly and that the final part has the desired mechanical properties. Cooling channels are typically integrated into the mold base, allowing water or other cooling fluids to circulate and regulate the temperature. Advanced cooling systems, such as conformal cooling, use 3D-printed channels that conform to the shape of the mold, providing more efficient cooling and reducing cycle times.

Injection tools play a vital role in the automotive industry, where precision and durability are paramount. Components such as dashboards, bumpers, and interior trims are all manufactured using injection molding. The tools used in this industry must be capable of producing parts with tight tolerances and high surface quality. Additionally, the materials used in automotive injection molding, such as high-performance plastics, require specialized tools that can handle the unique properties of these materials.

For more information on the tools used in automotive injection molding, visit our Automotive Injection Mold page.

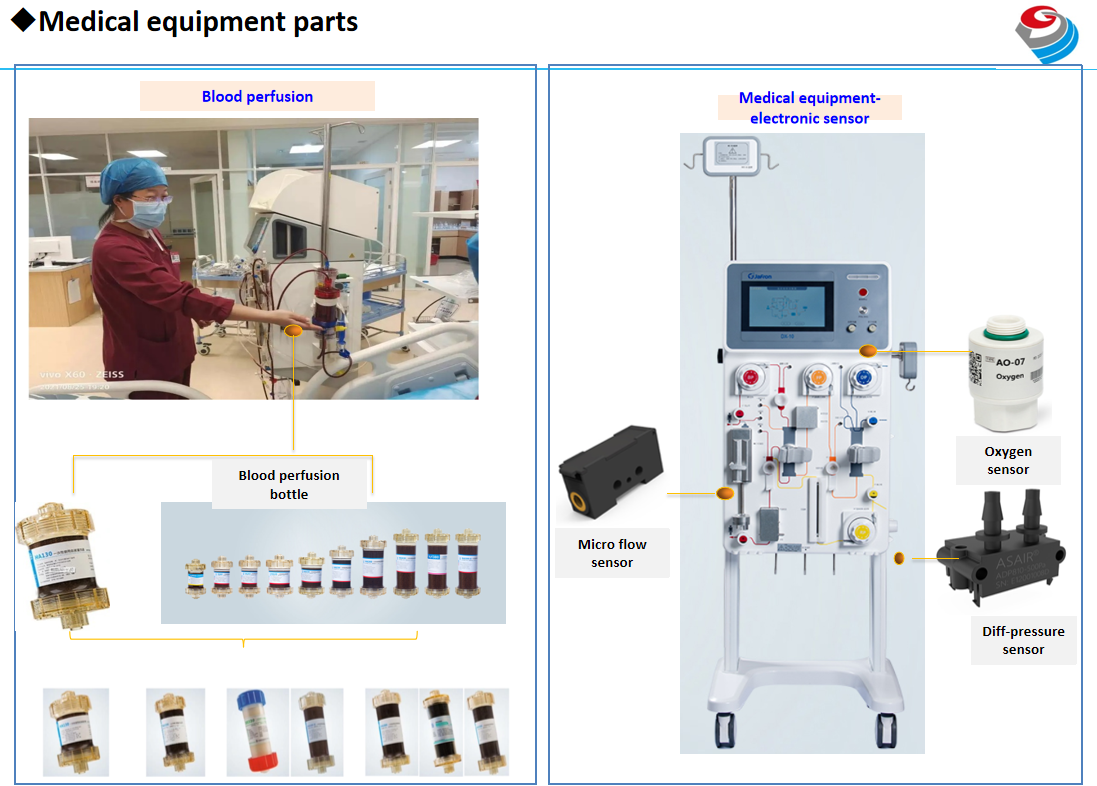

In the healthcare industry, injection tools are used to manufacture a wide range of medical devices, including syringes, IV components, and surgical instruments. These tools must meet stringent regulatory standards to ensure the safety and reliability of the final products. Additionally, the materials used in medical injection molding, such as biocompatible plastics, require specialized tools that can handle the unique properties of these materials.

Injection tools are also widely used in the consumer electronics industry to manufacture components such as housings, connectors, and buttons. The tools used in this industry must be capable of producing parts with high precision and excellent surface finish, as these components are often visible to the end user. Additionally, the materials used in consumer electronics, such as flame-retardant plastics, require specialized tools that can handle the unique properties of these materials.

One of the most significant advancements in the field of injection tools is the use of 3D printing to create molds. This technology allows for the rapid prototyping of molds, reducing lead times and costs. Additionally, 3D printing enables the creation of complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods. This has opened up new possibilities for the design of injection tools, particularly in industries that require highly customized parts.

Conformal cooling is another technological advancement that has revolutionized the design of injection tools. By using 3D printing to create cooling channels that conform to the shape of the mold, manufacturers can achieve more efficient cooling and reduce cycle times. This technology is particularly beneficial for high-volume production, where even small reductions in cycle time can lead to significant cost savings.

Smart molds are equipped with sensors that monitor various parameters during the injection molding process, such as temperature, pressure, and material flow. This data can be used to optimize the process in real-time, ensuring consistent quality and reducing the risk of defects. Smart molds are particularly useful in industries that require high levels of precision, such as the automotive and healthcare sectors.

Injection tools are the backbone of the injection molding process, enabling the mass production of high-quality plastic parts across various industries. From the mold base to the cooling system, each component plays a crucial role in ensuring the success of the process.

For more information on the latest innovations in injection molding, visit our Injection Mold page, where we offer a wide range of tools and solutions for various industries.

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.