| Availability: | |

|---|---|

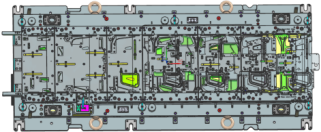

Electrical compo box

| Core and cavity steel | P20, 45#, D2, DC53 + nanocrystalline ceramic surface treatment, Gr12mo1v1, etc. |

| Standard parts | Panch, Misumi, etc. |

| Mold frame | self-made |

| Steel hardness | HRC60-62 |

| Material of stamping products | SGCC, SGCD2, DX56D, etc. |

| Number of cavities | 1X1 |

| Punching speed | 30SPM |

| Mold delivery time | 50-60 days |

| Mold delivery time | 300,000 times |

| Stamping die structure design: Adopt full 3D modular quick-change design (changeover time < 4H); |

| Stamping dieproduction efficiency: Mold parts adopt standard quick-change disassembly structure, which is for mold cost reduction, efficiency improvement and maintenance; |

| Stamping die accessories: Adopt integrated standard processing, parts can be used in multiple molds, ensuring the service life of the mold. |

| Production tools: Mold production is continuous mold production + automatic line punching machine robot production |

| High quality, higher tool ability |

| Manufacturability and reasonable price |

| On-time delivery |

| High quality, higher mold stability |

| Good after-sales service |

| Strict quality control |

| Reduce mold trials by 60%, and the first pass rate of complex bending parts is 91% |

We will provide you with a satisfactory mold solution. If you are looking for home appliance air conditioner electric control box mold, please come to us for inquiry, GDM has been established for 16 years and has rich experience in customizing sheet metal molds.

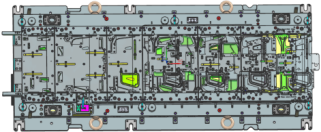

Electrical compo box

| Core and cavity steel | P20, 45#, D2, DC53 + nanocrystalline ceramic surface treatment, Gr12mo1v1, etc. |

| Standard parts | Panch, Misumi, etc. |

| Mold frame | self-made |

| Steel hardness | HRC60-62 |

| Material of stamping products | SGCC, SGCD2, DX56D, etc. |

| Number of cavities | 1X1 |

| Punching speed | 30SPM |

| Mold delivery time | 50-60 days |

| Mold delivery time | 300,000 times |

| Stamping die structure design: Adopt full 3D modular quick-change design (changeover time < 4H); |

| Stamping dieproduction efficiency: Mold parts adopt standard quick-change disassembly structure, which is for mold cost reduction, efficiency improvement and maintenance; |

| Stamping die accessories: Adopt integrated standard processing, parts can be used in multiple molds, ensuring the service life of the mold. |

| Production tools: Mold production is continuous mold production + automatic line punching machine robot production |

| High quality, higher tool ability |

| Manufacturability and reasonable price |

| On-time delivery |

| High quality, higher mold stability |

| Good after-sales service |

| Strict quality control |

| Reduce mold trials by 60%, and the first pass rate of complex bending parts is 91% |

We will provide you with a satisfactory mold solution. If you are looking for home appliance air conditioner electric control box mold, please come to us for inquiry, GDM has been established for 16 years and has rich experience in customizing sheet metal molds.

content is empty!

ZHUHAI GREE DAIKIN PRECISION MOLD CO., LTD.